Stop losing orders. Learn how to reduce the cost per part!

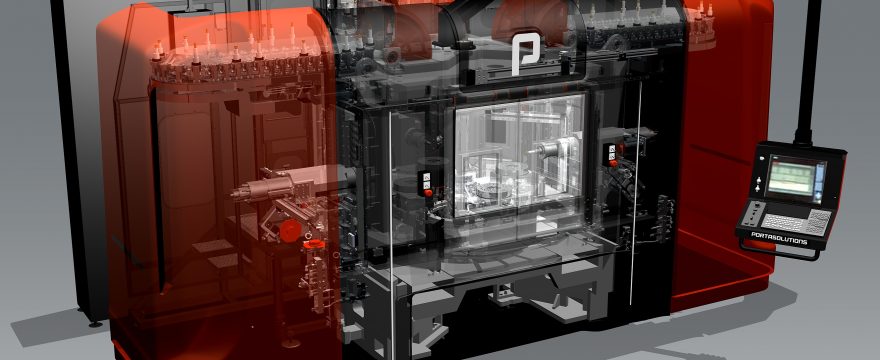

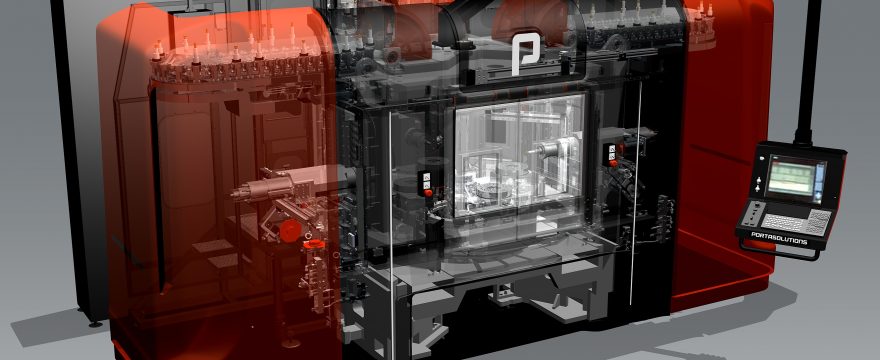

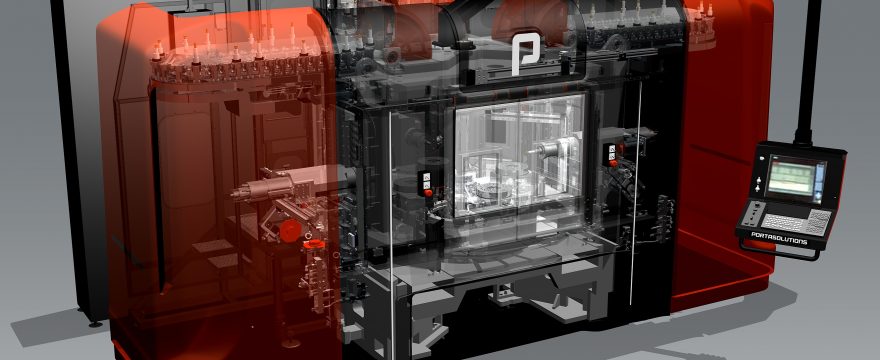

In today’s industrial scenario, technology is playing an increasingly decisive role in ensuring the competitiveness of companies in the manufacturing industry. Keeping operational costs low, optimizing resources, and responding quickly to market demands are daily challenges for businesses. It is precisely in this context that the PORTACENTER represents a revolutionary solution capable of transforming the entire production chain.

In this article, we will explore in detail the numerous advantages the PORTACENTER offers to companies and how this machining center can become a key tool for improving production performance without resorting to external solutions like outsourcing.

The Strategic Role of Technology in Manufacturing

In recent years, the manufacturing industry has undergone a radical transformation. The integration of new technologies has enabled improvements in efficiency, cost reduction, and greater flexibility and responsiveness to changes in the global market. However, for many companies, adopting innovative technologies remains a significant challenge, especially when balancing the initial investment with economic returns in the mid-long term.

The PORTACENTER fits perfectly into this context as a concrete and tangible solution to these challenges. This flexible and highly innovative machining center offers a series of benefits that make it a strategic option for manufacturing companies.

1- Cost per Part Reduction: The Ultimate Competitive Advantage

One of the main obstacles many companies face is high part cost, which often lead to considering production outsourcing to low-cost labor countries. However, the PORTACENTER provides a valid alternative. Thanks to its advanced design and ability to optimize machining times, this tool allows for significant reductions in part cost.

Keeping production local not only improves product quality but also eliminates the logistics and management costs associated with outsourcing. Additionally, having the production site close to the target market enables faster and more flexible responses to customer demands.

2- Optimizing Production Area: Get More with Less

In many companies, optimizing space is a primary challenge. Purchasing or renting new production spaces can be expensive, especially in highly developed industrial areas. The PORTACENTER stands out for its space-efficient design: compared to traditional machining centers, it occupies less space, allowing for maximum productivity in smaller areas.

This feature helps reduce real estate costs and optimize internal organization without sacrificing production capacity. Moreover, thanks to its modularity, the PORTACENTER can be easily adapted to different production configurations.

3- Reducing the Need for Specialized Labor: Efficiency Without Compromise

Another significant advantage of the PORTACENTER is its ability to reduce the need for highly specialized labor. In many production environments, the demand for skilled operators is one of the primary factors driving up operational costs.

With the PORTACENTER, various phases of the production process can be automated while maintaining a high level of quality.

This automation allows companies to reduce personnel costs without compromising productivity. Operational management becomes leaner, with smaller yet equally efficient teams.

4- Saving on Fixture Costs: Lower Investment, Higher Returns

The purchase and maintenance of fixtures represent a significant expense for many companies. Thanks to its innovative configuration, the PORTACENTER requires fewer fixtures than traditional machining centers. This means lower initial and maintenance costs.

Companies that choose the PORTACENTER can thus invest less capital at the beginning, achieving a quicker return on investment. Additionally, the simplification of fixture reduces the risk of breakdowns and downtime, improving production efficiency.

5- Energy Efficiency: A Sustainable Choice

Sustainability is becoming increasingly important for manufacturing companies. The PORTACENTER, designed to minimize energy consumption, offers an efficient solution that helps companies reduce energy costs while also lowering environmental impact.

This not only results in immediate economic savings but also aligns companies with sustainability goals increasingly demanded by the market and environmental regulations at both national and international levels. The PORTACENTER is, therefore, a strategic choice for companies aiming to reduce their environmental footprint.

6- Flexibility and Innovation: Get Ready for the Future

Flexibility is another key strength of the PORTACENTER. In an ever-changing world where market demands shift rapidly, companies must be ready to respond promptly. Thanks to its modular and flexible configuration, the PORTACENTER enables companies to quickly adapt to production changes and continuously innovate their processes.

This responsiveness is essential for maintaining competitiveness in a globalized and constantly evolving market.

7- Collaboration and Communication: An Integrated Production

Lastly, the PORTACENTER facilitates collaboration and communication among different company teams. By enabling more efficient resource management, this system improves the company’s responsiveness to market demands.

An integrated and well-communicated production flow between different departments helps avoid mistakes, reduce downtime, and optimize production processes.

Why Choose the PORTACENTER?

The PORTACENTER is an innovative solution that can deeply transform how manufacturing companies manage production. Reducing operational costs, increasing energy efficiency, enhancing flexibility, and minimizing the need for specialized labor are just some of the advantages this system offers.

If you’re looking for a way to make your company more competitive and reduce costs without compromising quality, the PORTACENTER could be the right solution you’ve been searching for.

Phone: +39 030 800673

Email: info@portaproduction.com

To your results,

Maurizio Porta

Master Trainer PORTA PRODUCTION METHOD