The study for the calculation of cycle time and piece cost on the machining operation of one or more components is a complex operation which, at the same time, is almost never 100% true and verified.

This is until the moment in which the machine starts production.

The studies offered by machine tool manufacturers remain only pieces of paper until they find direct PRACTICAL APPLICATION on the machine tool on which such calculations have been made and put into production.

If you deal with machining operations on metal parts and want to evaluate a new plant to work a component or a new family of components and to get new orders, relying only on a study (on a piece of paper) to decide which machine to buy is a very risky choice.

Without the support of a practical test, you risk making wrong choices and mistakes that could cost the production department and the company dearly.

Because basically the facts are on the ground.

Until you have evidence from numbers, we’re just talking about so many beautiful promises that could be very far from reality and immediately denied when tackling a machining operation.

And I’ll tell you more.

Even if you include the cycle time in the contract, written down on paper, with the aim of binding it to the withdrawal of the machine, when it’s time to test, even if you can assert your right, how much more time should you take to find another solution?

This is called “reaction time” and it represents the time frame in which an equally valid alternative solution is identified.

But several studies and experience in the field show that prevention is better than cure, so it is certainly better to be able to reduce the margin of error (given that there’s no way to eliminate it).

But above all it is necessary to put yourself in the shoes of your customers, who are among the first stakeholders of your company and who count on you and the reliability of your services.

What would you tell them? That you have not been able to select the right supplier of the machine?! It is not easy to explain.

It is therefore necessary to look for a machine tool manufacturer who, within his proposal, is able to offer a service to solve this important problem.

A duty that turns into a concrete and immediate advantage, especially when we talk about machine tools for machining operations.

Do you want an example? Here it is!

CNC machining operations: the fear of making a wrong investment

Let’s say you are a user of CNC machining centers and you are used to working with this kind of machine tools, to which you are very fond and of which you know every single detail.

Obviously this situation generates a sense of “safety” that leads you to always make the same purchase choice for other machine tools.

In most cases you will tend to buy more and more machining centers and probably always the same ones, from the same brands and the same manufacturers. You will hardly move on to different and alternative solutions, although in some cases numbers could clearly prove you are wrong.

This situation is well defined in psychology and is called “cognitive bias“.

A mental process created by our brain that bends the truth, changing the perception we have of things as a shield of “self-defense”.

Exactly, because our brain is naturally set to make us avoid pain.

We tend to escape from the unknown, trusting only things we already know.

We can think about this situation as an inner voice that tells us:

“Don’t change your situation, stay where you are, keep on buying the same machines. You’ve always felt good, haven’t you? After all, you’ve always done so, why change it now? Don’t do it, stick to old habits … “

But anyone with a little experience knows that “old habits = old results“, which is just the opposite of improvement and innovation.

If you are not aware, this mental dialogue becomes a dangerous double-edged sword and it could destroy your company.

If, on one hand, your brain is trying to protect you from external events and potential dangers, on the other hand, in many cases, it is doing damage, because it makes you lose opportunities for improvement.

This happens because both you and I are naturally set to always do the same things.

But, as an expert in this sector, I have to tell you that this is not healthy, because if you continue to only ever buy the same machines, relying on the same old solutions, you will continue to give a competitive advantage to your competitors.

Test and continuous improvement are the basis of production companies that grow and win on the market.

So which is the solution?

Of course, there isn’t a magic wand. But the correct approach is to realize that the solution comes by testing, looking for new alternative solutions to those we have always used. At the risk of experiencing discomfort and insecurity, inevitable for anyone aiming to improve.

I understand that you may be afraid of changing, because if you make a mistake buying a machine tool, you will probably be fired on the spot, causing damage not only to the company you work for, but also to the people around you.

I fully understand it.

Only the most enterprising people, with a strong desire to innovate, are willing to expose themselves to the unknown, to explore new solutions to be adapted to their sector, to bring new added value to the company.

And this also applies to the world of CNC machining operations.

It’s important to rely on machine tool manufacturers who can guarantee you a direct test on the type of machine you want to buy:

- with the family of components you have to work with;

- with the correct equipment you want to use;

- concretely carrying out the processing operations you will do in your production department.

But let’s see in detail the main advantages of the Test Drive.

CNC machining operations: the advantages of the “ZERO RISK” Test Drive

The Test Drive is the most important aspect to consider, because it helps you make that mental leap that freezes you, preventing you from changing.

The cognitive bias mentioned above is the first real obstacle that does not allow you to serenely face the change.

With the Test Drive you can overcome this obstacle in a safe and strategic way.

Here are the main advantages of the Test Drive:

- The possibility to test the machine BEFORE it arrives in your company.

- The possibility to test EQUIPMENT.

- Check whether the CYCLE TIME presented to you in the study is true or whether it has been fixed.

- Make changes and improvements in real time, even before buying the machine.

- Check the set up time from one product to another, verifying the ease of execution and what the manufacturer promised.

All this before your eyes, without the risk of making a wrong investment, buying a new system only on the basis of what the manufacturer writes on a piece of paper.

How to reduce the risk of buying a new machine tool

Thanks to this service, another important concept is introduced: reverse risk.

The reverse risk is the practice that allows the buyer to NOT RISK anything, not to have to make decisions based on theoretical facts that he cannot control.

One day I asked myself:

“Why do people have to trust what I say and hope is true?”

“Why does the buyer, and end user, have to bear 100% of the risk in purchasing decisions?”

Thanks to these questions and the obsessive search for service improvement, the idea of the “ZERO RISK” Test Drive was born.

What is that?

It is a service that allows you to reverse the risk, that is (said in a super simple way): “If I promise you something (a benefit, a result), then I have to bear the business risk, not you as my customer.”

It is simple, isn’t it?

Actually, it isn’t, or at least not for everyone.

Furthermore, if you work well, the risk is practically close to zero. I guarantee with my experience of over 25 years in this sector.

Then, once it has been proven that what was promised is true, I will no longer have to sell anything, because the customer will be free to decide whether he wants to buy the machine or not.

And that’s the reason why I have no salesmen in my company, but I decided to create a team of Technical Tutors, experts in machining operations, who make the “ZERO RISK” TEST DRIVE service possible.

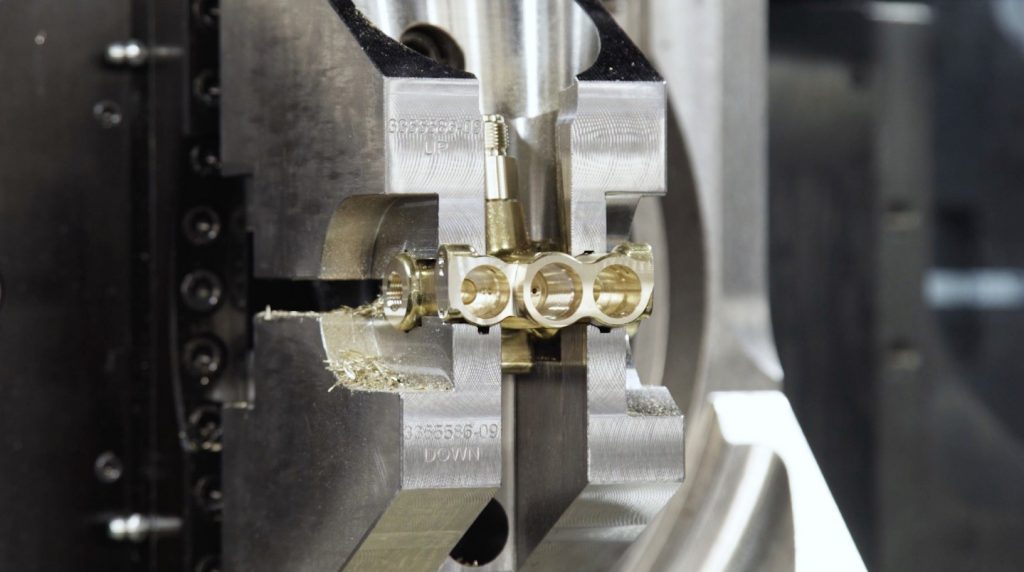

In the image below you can see an example of a TEST DRIVE in progress, carried out together with a customer at our American headquarters, Porta North America Inc..

The test was carried out on a PORTACENTER, a machine tool with 3 independent SPINDLES, which allows to produce 3 times faster than a single machining center, remaining flexible thanks to the SMED system which guarantees a production change in just 15 minutes.

3 Spindles = 3 times faster than 1 single machining center

And all this, as mentioned, while remaining super flexible!

With this machine you can carry out machining operations on ferrous materials such as steel, brass, cast iron, aluminum, for different fields such as Automotive, Oil&Gas, taps, earth-moving works …

Thanks to the systems and parameters of the PORTA Production Method, we can identify the correct production balances, to increase the efficiency of each individual project and machining operation that the customer requires.

Being more efficient means LOWERING THE PIECE COST.

Lowering the piece cost means BECOMING MORE COMPETITIVE.

Becoming more competitive means WINNING MORE ORDERS.

The PORTA SOLUTIONS Test Drive service is present:

– in Europe >>> Italy, in Villa Carcina (BS)

– in America >>> U.S.A., in Charlotte (NC)

For more information on the “Studio + Test Drive” service, just write to the email address tutor@portaproduction.com expressing your interest in learning more about this topic and the will to receive an offer for the Test Drive for you.

Visit this page and fill out the form to ask for more information:

www.porta-solutions.com/test-drive

WRITE YOUR EMAIL in the form below to receive the video of a Test Drive created by PORTASOLUTIONS for a European customer.

DOWNLOAD THE VIDEO NOW!

If there is a thing that I will never tire of saying, as Master Trainer of the PORTA Production Method, it is that in many cases it is essential to do what is correct and right, not what you like.

And if the market tells us to change (and to change quickly), we cannot think of doing it by always remaining stuck on the same working methods and procedures, using the same machine tools.

If you have only ever bought and used machining centers, it’s time to ask yourself if this is really the best solution to follow up your company.

There is a need for innovation and continuous research and the TEST DRIVE is the right tool to deal with change to the best.

The PORTA Production Method was created precisely for this reason, to help production companies that use CNC Machining Centers and Twin-spindle Centers for metalworking to face the change and make their production departments as efficient as possible.

MORE EFFICIENCY

=

MORE ORDERS / MORE PROFIT

=

MORE CORPORATE WELFARE,

FOR SHAREHOLDERS AND STAKEHOLDERS

If you are a user of CNC Machining Centers and Twin-spindle Centers for metalworking and you want to understand how to innovate and win in the market, lower the production risk and obtain the best balance for your company … NOW you have the opportunity to do these studies together with a Technical Tutor, an expert in the field who will guide you, step by step, in finding the best production model for your specific case.

Ask for a FREE consultation with one of our TECHNICAL TUTORS.

Phone: +39 030 800673

Email: info@portaproduction.com

To learn more about Competitive Production and PORTA Production Method

CLICK HERE >>> www.machiningcentersbook.com <<<

My book dedicated to users of machine tools who want to make the leap in quality is waiting for you!!!

To your results, Maurizio Porta

Master Trainer PORTA PRODUCTION METHOD

Leave a Reply