Stop losing orders. Learn how to reduce the cost per part!

/ R&D / Maurizio Porta

The manufacturing sector is undergoing a period of rapid transformation, driven by the adoption of new technologies that are redefining production processes.

For companies looking to stay competitive, understanding emerging trends and implementing targeted strategies to leverage them is essential.

In this article, we explore the key technological innovations shaping the manufacturing industry in 2025.

Artificial intelligence has become a crucial component for optimizing production processes.

Machine Learning algorithms enable:

Investing in AI allows for smarter and more dynamic production processes.

Collaborative robots (cobots) are revolutionizing factory work. These tools are designed to work alongside human operators, enhancing productivity without compromising safety.

Key advantages include:

The Internet of Things (IoT) is transforming production facilities into connected and intelligent environments.

IoT devices allow for:

Smart Factories represent the future of manufacturing.

Sustainability is becoming an increasing priority in the manufacturing sector. Adopting technologies that reduce environmental impact is essential for compliance with regulations and meeting customer expectations.

Porta Solutions has been implementing sustainable practices for years, both in production processes and corporate infrastructure. The PORTACENTER Machining Centers are designed to ensure reduced energy consumption, contributing to greater efficiency and sustainability.

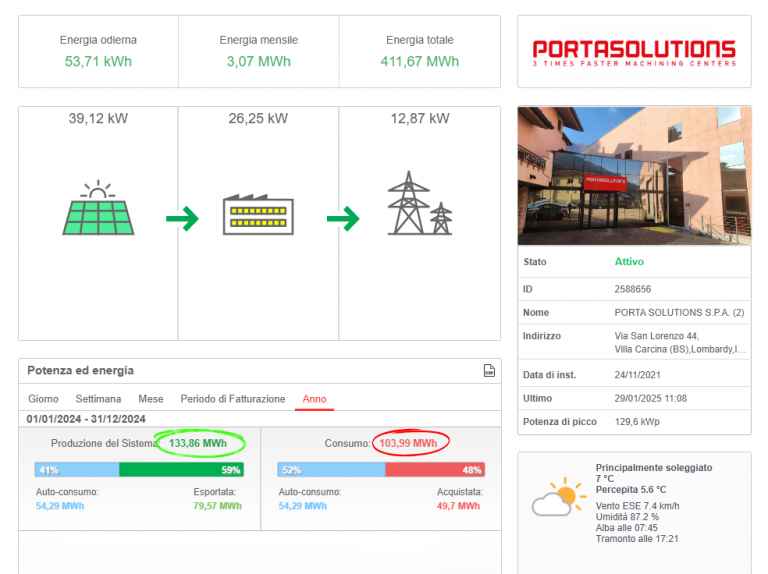

Additionally, the company uses a photovoltaic system, making Porta Solutions nearly self-sufficient in meeting its daily energy needs.

Common sustainable solutions include:

A “digital twin” is a virtual replica of a product, process, or system.

This technology allows for:

Porta Solutions uses Digital Twin technology to optimize the performance of its PORTACENTER Machining Centers, offering customers the ability to simulate the entire production process before implementation.

This approach helps identify inefficiencies, improve productivity, and minimize operational risks, ensuring customized solutions for every manufacturing need.

Find out how Porta Solutions’ Digital Twin can transform your production processes!

👉🏻 Contact us now for a personalized consultation and start leveraging the full potential of our innovative solutions.

For manufacturing companies, adopting these technologies means investing in training, infrastructure, and strategic partnerships.

Here are some practical steps:

Initial Analysis: Assess specific needs and identify areas for improvement.

Training: Engage employees in training courses on new technologies.

Collaboration: Work with suppliers and technology partners to implement customized solutions.

2025 marks a crucial year for the manufacturing sector, presenting unprecedented opportunities for those willing to innovate.

Companies that leverage emerging technologies will not only remain competitive but will also become industry leaders.

Keep up with the latest innovations in the manufacturing sector and keep up with Porta Solutions!

To your results,

Maurizio Porta

Master Trainer PORTA PRODUCTION METHOD