One of my greatest passions is, without a doubt, running.

It’s a passion I’ve been cultivating for several years now. I like running and doing marathons because to me, they’re a metaphor for life and a way to challenge yourself, to put yourself out there, and to help keep your body in shape.

The title I used is a bit ridiculous for a very specific reason.

The discipline needed for running and marathons can be compared to manufacturing companies and production departments, where it is important to maintain certain performance levels if you want to stay in the race.

When running, if you want to win or at least stay among the leaders, you have to be well-trained but that isn’t enough. You also need to have a precise strategy upstream and the right means to support you during the competition.

If you want to win or be one of the first, you can’t make mistakes.

There can be multiple correct means in a marathon and they can affect several factors.

Among these means, one of the most important is surely the choice of shoes.

Choosing the right shoes is essential to be able to race at your best and keep your performance level high during the entire marathon.

Do you think it’s possible to race in elegant shoes? The kind you would wear for an evening at the theatre? It might be, but you’d get to the finish line last and exhausted or you’d almost certainly be forced to withdraw because of the overwhelming pain.

What am I trying to say using this metaphor?

Try to imagine running a marathon in elegant office shoes.

What would happen is that even the best marathon runner, despite the potential to win the race, having trained to perfection, would not be able to do so wearing this type of shoe.

Any coach with an ounce of common sense would point out to the marathon runner how impossible it would be to win the race, no matter how great the commitment, effort and dedication. The coach would immediately switch the shoes with a pair of sneakers and …off to the races!

Wearing a pair of running shoes, the marathon runner would go much faster and his/her body would be properly balanced while running.

Alright, although definitely an intense metaphor, it is useful in order to understand how important it is to choose the proper, appropriate means to keep performance levels high.

What do Production Departments and marathons have in common?

The situation is not much different in production departments.

I often see companies using less-than-ideal means to try and obtain certain results that, instead, require other means and methods.

Let’s take the classic example of a production department that wants to increase output.

The most common choice is to increase the number of machines. How? By purchasing a battery of Machining Centers because the basic reasoning is: “If I increase the number of systems, I can also increase the number of units produced in the same amount of time.”

But this reasoning is completely wrong.

To increase your department’s output, you can’t use means that aren’t appropriate for this specific goal.

When you want to increase output WITHOUT simultaneously increasing costs, Machining Centers are like elegant shoes.

TO INCREASE PRODUCTION SPEED, YOU NEED TO CHANGE YOUR SHOES … and choose a pair of sneakers that will allow you to drastically change your running speed while also saving on management costs.

Shoes are the primary means that you need to increase your running speed.

To increase your production department’s output, you can’t keep only using Machining Centers, taking up more space, personnel, energy consumption, automation. You have to change the means!

What does increasing the number of machines entail?

Continuing to increase the number of machines is a double-edged sword.

If, on the one hand, you increase production, on the other, COSTS increase drastically and this will go on to affect the final cost per part of the components you manufacture.

If you increase the cost per part, there are only two possible paths:

- KEEP THE SAME MARKET PRICE, eroding your company’s margins and jeopardizing going-concern indices.

- INCREASE THE MARKET PRICE to keep the same margins but almost certainly risking losing market shares.

Continuing to increase the number of machines, as mentioned, entails a series of significant costs that absolutely requires your attention.

They are listed below:

- EQUIPMENT COSTS – More machines equals equipment costs, which increase considerably.

- PERSONNEL COSTS – Having many machines that are constantly increasing requires more specialized personnel.

- ENERGY COSTS – Every added system entails increased energy costs.

- OCCUPIED AREA COSTS – Do you want to increase output with the “battery of Machining Centers” model? This entails an increase in warehouses and the area required to house the new systems.

As you can see, the business model based on constantly increasing the number of Machining Centers to promote department output involves many issues that, if not managed and contained in time, can lead to a point of no return.

A company that follows this model could quickly see drastically reduced margins, which must be countered by raising prices.

Unless…

The right means and strategy to win the marathon in your production department.

As mentioned previously, to win a marathon, you have to switch shoes, that is, use the right means to increase your running performance.

The main parameter that you have to prioritize to keep the level of competition high is the COST PER PART.

Therefore, it’s a good idea to identify a means that can ensure the best result for this parameter.

The means a company installs in its production department must include the following advantages and features:

- Have a low EQUIPMENT COST.

- Keep the need for SPECIALIZED PERSONNEL low.

- Contain ENERGY costs.

- Be able to increase output in the SAME SPACE, thereby avoiding having to expand the establishments to produce more.

- Have high production CAPACITY and SPEED.

- Keep the production department LEAN and FLEXIBLE.

To obtain all of these advantages, today there is a new category of Machine Tools for metalworking: 3-spindle Machine Tools.

Three-spindle Machine Tools are machines that contain the flexibility of Machining Centers in just one system, with a production speed up to 3 times faster than a single Machining Center.

This means having two immediate benefits:

- Reducing CYCLE TIME, thanks to the noticeably superior production speed.

- Reducing COST PER PART because the costs of managing this type of machine are without a doubt lower than a battery of Machining Centers.

PRODUCE MORE IN THE SAME SPACE

LESS MACHINES = LESS COSTS

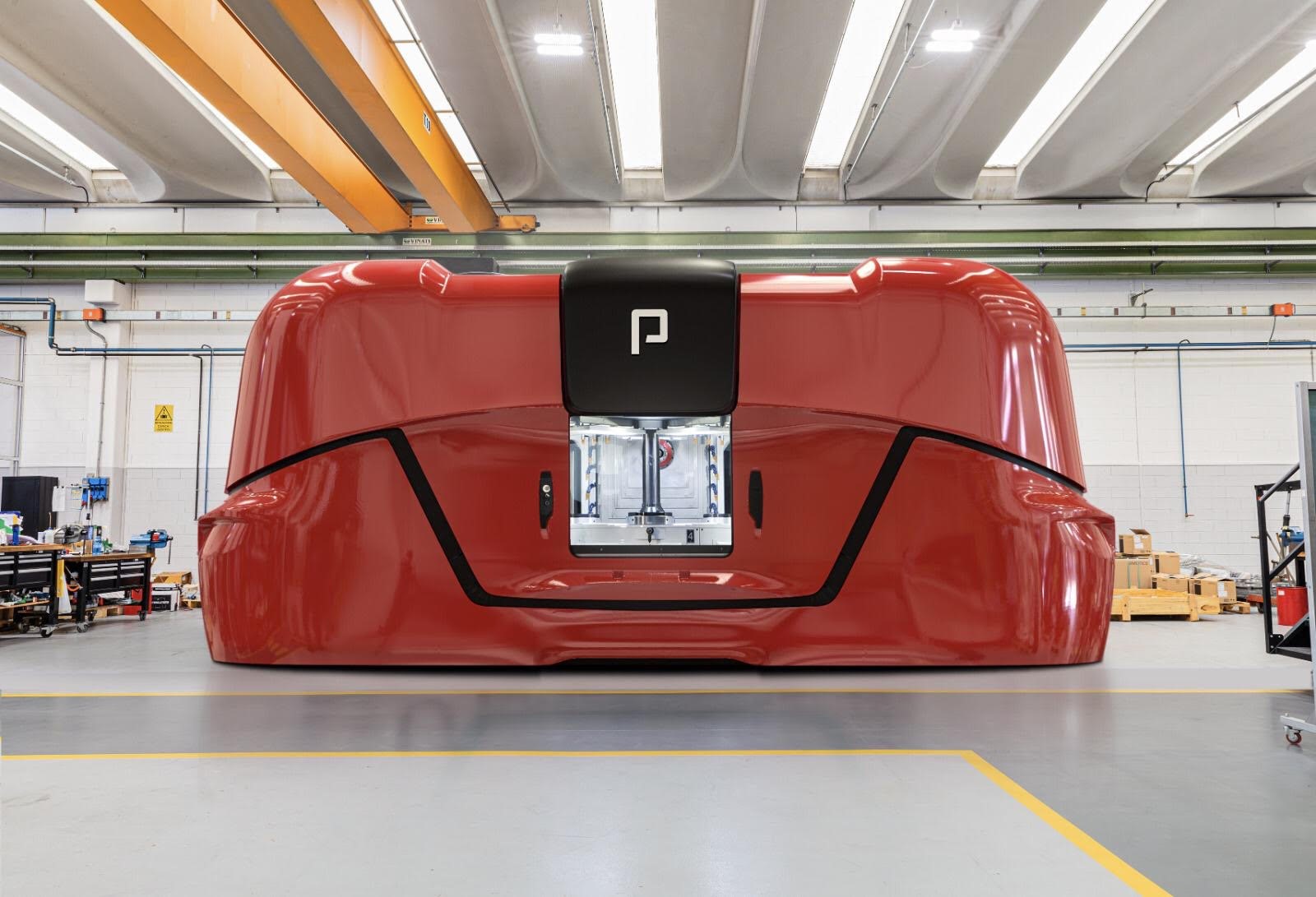

The 3-spindle machine par excellence, the leader in its category, is the PORTACENTER by Porta Solutions S.p.A., which now counts over 400 centers in production and whose know-how on this specific category of machines dates back to 2005.

A know-how built over time that allows the company to transfer this advantage to its customers as well, thanks to 3-spindle machines with maximum production RELIABILITY and PERFORMANCE, based on the technology of the 3 TOTALLY independent spindles on the XYZ axes and rotating B axis.

The PORTACENTER is the right means to win your marathon.

It represents the running shoes you need to increase your running speed (of production) and compete with a means that is completely different compared to a battery of Machining Centers.

The latter, as mentioned, is inadequate for the task of increasing department output. Sure, there are some that are very modern, but the concept is stuck in time 20 years ago.

What Machining Center manufacturers continue to improve is the product in itself (a spindle with pallet exchange, maybe faster). This is surely a good thing, but the real improvement in quality comes from analyzing what the end customer needs to reduce the cost per part!

To compete today, you have to slash cycle times and the cost per part.

The PORTACENTER allows you to optimize these two parameters and competitiveness indicators to the utmost.

Here is a summary of the PORTACENTER’s strengths that will have you wearing your sneakers, while your competitors keep running in their elegant shoes:

- VERY FLEXIBLE, it adapts to all materials and pieces to be processed.

- SUPER FAST TOOLING: piece change in 15/20 minutes.

- FAST PRODUCTION, with 3 spindles always in operation!

- LOWER TOOLING COSTS compared to conventional Machining Centers.

- LOWEST INVESTMENT COST in its category, thanks to mass-production.

- QUICK DELIVERY, in 30/60 days.

As mentioned previously, the right means requires the right strategy and method that can support the production department’s need to increase output.

That is why, thanks to over 25 years of direct experience in this sector, I came up with the PORTA Production Method, a method based on specific principles for production departments that want to increase production speed and compete using means other than conventional Machining Centers.

You can read about my Method in detail in the book I wrote just for multiple Machining Center users like you. It’s available for purchase at the following link:

www.machiningcentersbook.com

In the book, I explain exactly which dangers and errors to avoid at all costs in your production department.

You will also find all the right means your company needs to reduce cycle times, slash the cost per part, and earn more.

Now it’s your turn!

Do you want to keep running marathons in shiny shoes that are ill-suited for someone who wants to compete and win the race?

Or do you want to finally put on the best running shoes to become faster and increase your production department’s output?

REMEMBER: it is not the strongest who survive but those who quickly adapt to new scenarios!

Ask for a FREE consultation with one of our TECHNICAL TUTORS.

Phone: +39 030 800673

Email: info@portaproduction.com

To learn more about Competitive Production and PORTA Production Method

CLICK HERE >>> www.machiningcentersbook.com <<<

My book dedicated to users of machine tools who want to make the leap in quality is waiting for you!!!

To your results, Maurizio Porta

Master Trainer PORTA PRODUCTION METHOD

Leave a Reply